IsiKhokelo seNkqubo yeMveliso yeLeaf Springs

-Ukucofa (ukucofa ixesha elide kunye nokucofa okufutshane)(Icandelo 3)

1. Ingcaciso:

Inkqubo yeTapering/Rolling: Ukusebenzisa umatshini wokuqengqeleka ukucofa imivalo ethe tyaba yasentwasahlobo enobunzima obulinganayo kwimivalo yobukhulu obahlukeneyo.

Ngokubanzi, kukho iinkqubo ezimbini zokucofa: inkqubo yokucofa ixesha elide kunye nenkqubo yokucofa imfutshane. Xa ubude be-tapering bungaphezulu kwe-300mm, kubizwa ngokuba yi-long tapering.

2. Isicelo:

Onke amagqabi entwasahlobo.

3.1. Ukuhlolwa ngaphambi kokuqhawula

Ngaphambi kokuqengqeleka, jonga uphawu lokuhlola lokubhobhoza (ukugaya) umngxuma weziko le-spring bar bars kwinkqubo yangaphambili, ekufuneka ifaneleke; ngexesha elifanayo, qinisekisa ukuba ukucaciswa kweebhari ze-spring flat ziyahlangabezana neemfuno zenkqubo yokuqengqeleka, kwaye inkqubo yokuqengqeleka ingaqalwa kuphela xa ihlangabezana neemfuno zenkqubo.

3.2. Ukugunyazisa aumatshini wokuqengqeleka

Ngokweemfuno zenkqubo yokuqengqeleka, khetha indlela ethe tye okanye i-parabolic rolling. Ukuqengqeleka kovavanyo kuya kuqhutywa ngokumiswa kwesiphelo. Emva kokuba uvavanyo luphumelele ukuzihlola, luya kuthunyelwa kumhloli ukuze luphononongwe kwaye luvunywe, kwaye ke ukuqengqeleka okusesikweni kunokuqaliswa. Ngokuqhelekileyo, ukususela ekuqaleni kwe-tapering ukuya kwi-rolling yamaqhekeza angama-20, kuyimfuneko ukukhuthala ekuhloleni. Xa uqengqeleka iziqwenga ezi-3-5, kuyimfuneko ukujonga ubungakanani bokuqengqeleka kanye kwaye uhlengahlengise umatshini wokuqengqeleka kanye. Ukuhlolwa okungaqhelekanga kunokwenziwa ngokuphindaphindiweyo ngokuphindaphindiweyo kuphela emva kobude bokuqengqeleka, ububanzi kunye nobukhulu buzinzile kwaye bufanelekile.

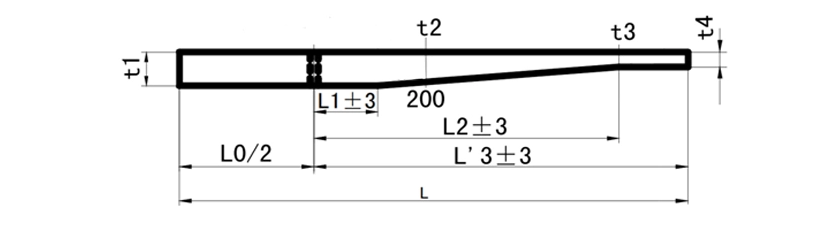

Njengoko kubonisiwe kuMfanekiso 1 ngezantsi, iparameters useto lweukuqengqeleka kwentlakohlaza yamagqabi.

(Umfanekiso 1. Iiparamitha eziqengqelekayo zentlakohlaza yamagqabi)

3.3.1. Iinkcazo zobunzima bokuqengqeleka

Ukuqengqeleka kobunzima t1 ≥24mm, ukufudumeza ngesithando somlilo esiphakathi.

Ukuqengqeleka kokuqina kwe-t1<24mm, isiphelo seziko lokufudumeza sinokukhethwa ukufudumeza.

3. Iinkcazo zezinto zokuqengqeleka

Ukuba izinto eziphathekayo60Si2Mn, ubushushu bokufudumala bulawulwa kwi-950-1000 ℃.

Ukuba izinto eziphathekayo ziyi-Sup9, ubushushu bokufudumala bulawulwa kwi-900-950 ℃.

3.4. Ukuqengqeleka kunyeukusika iziphelo

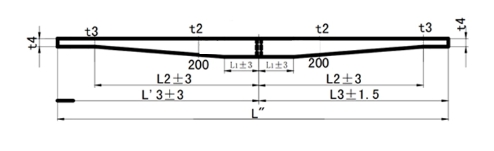

Njengoko kubonisiwe kuMfanekiso 2 ngezantsi. Misa isiphelo sebhari ekhohlo kwaye uqengqe icala lasekunene lasekunene lebha ngokweemfuno. Emva kokuba i-tapering ihlangabezane neemfuno zobungakanani, nqumla isiphelo esifanelekileyo ngokobungakanani boyilo. Ngokufanayo, ukuqengqeleka kunye nokuphela kokusika ngasekhohlo ibha yeflethi iya kwenziwa. Iimveliso eziqengqelekayo ezide kufuneka zilungiswe emva kokuqengqeleka.

(Umfanekiso 2. Iiparamitha zokucofa intlasa yamagqabi)

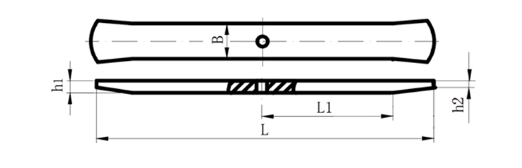

Kwimeko ye-tapering emfutshane, ukuba ukunqunyulwa kwesiphelo kuyafuneka, kwaye iziphelo ziya kucuthwa ngokwendlela engentla. Ukuba ukunqunyulwa kokuphela akufuneki, iziphelo zentwasahlobo yeqabunga zibukeka njengefeni. Njengoko kubonisiwe kuMfanekiso 3 ngezantsi.

(Umfanekiso 3. Iiparamitha ezimfutshane zokucofa kwintlakohlaza yamagqabi)

3.5. Ulawulo lwezinto eziphathekayo

Iimveliso ezigqityiweyo ezigqityiweyo zokugqibela ziya kupakishwa kwi-rack ye-material kunye ne-flat-straight surface ezantsi, kwaye uphawu lokuhlola isiqinisekiso sobukhulu obuthathu (ubude, ububanzi kunye nobukhulu) luya kwenziwa, kwaye ikhadi lokudlulisa umsebenzi liya kuncamatheliswa.

Akuvumelekanga ukuphosa iimveliso ngeenxa zonke, kubangela umonakalo ongaphezulu.

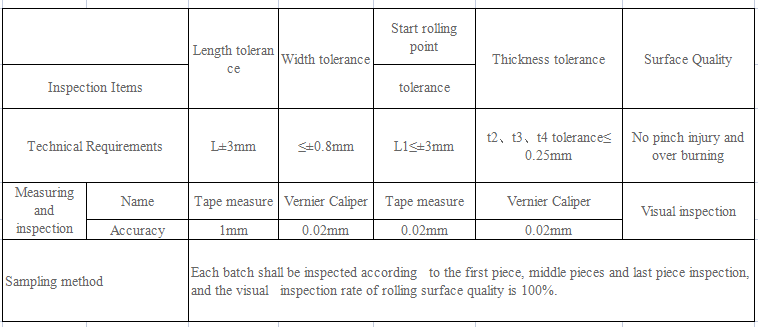

4. Imigangatho yokuhlola (Jonga kumgangatho: GBT 19844-2018 / ISO 18137: 2015 MOD Leaf Spring - IiNkcazo zoBugcisa)

Ukulinganisa iimveliso ezigqityiweyo ngokomfanekiso 1 kunye noMzobo 2. Imigangatho yokuhlolwa kweemveliso eziqengqelekayo iboniswe kwiThebhile 1 ngezantsi.

Ixesha lokuposa: Mar-27-2024